After spending many years working with sulfur curing systems, I have learned one simple rule: an accelerator is only “good” if it performs well not just in the lab, but on the factory floor. Many newcomers focus too much on cure speed alone, while experienced compounders know that stability, dispersion, and handling are just as critical.

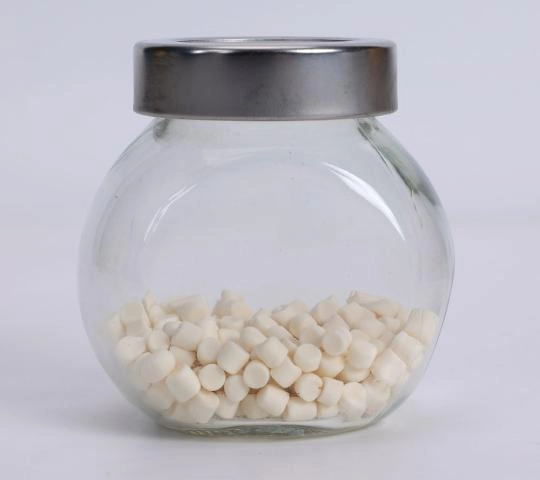

This is exactly where MTT-80 pre-dispersed masterbatch stands out. It takes the well-established chemistry of MTT and transforms it into a form that aligns with today’s production realities—high output, tight quality control, and rising safety expectations. In this article, I’ll walk you through why MTT-80 has become a dependable choice for many rubber manufacturers, especially those scaling up or refining their processes.

Enhancing Vulcanization Performance with MTT-80

At its core, MTT-80 is an effective rubber accelerator masterbatch for sulfur vulcanization systems. Its primary role is to promote efficient crosslink formation, ensuring that rubber compounds reach the desired state of cure within a controlled time window.

Compared with powdered MTT, the pre-dispersed format allows the active accelerator to be distributed more evenly throughout the compound. This uniformity directly translates into more consistent vulcanization performance, especially in formulations where precise cure behavior is required. In practical terms, manufacturers often observe more predictable torque curves and fewer deviations in final mechanical properties.

Balanced Cure Speed and Processing Safety

One of the most common mistakes I see among beginners is chasing faster cure speeds at the expense of processing safety. MTT-80 offers a much better balance.

Thanks to its controlled dispersion and carrier system, MTT-80 delivers moderate, well-managed cure acceleration without significantly increasing scorch risk. This makes it easier to maintain processing stability during mixing, calendering, extrusion, or molding operations.

For plants running continuous or semi-automated lines, this balance is crucial. It allows operators to maintain steady production without constantly worrying about premature vulcanization or narrow processing windows.

Cleaner Production with Dust-Free Handling

Anyone who has handled powdered accelerators knows the drawbacks: dust clouds, material loss, and unnecessary exposure risks. MTT-80 addresses these issues directly.

As a pre-dispersed, dust-free rubber accelerator, MTT-80 significantly improves workplace cleanliness. Weighing and feeding become simpler, losses are reduced, and operators can work more comfortably and safely. Over time, these improvements contribute to better compliance with occupational health standards and a more controlled production environment.

From my experience, cleaner handling is not just about safety—it also improves dosing accuracy, which further enhances compound consistency.

Improved Dispersion and Mixing Consistency

Dispersion is often the hidden factor behind inconsistent rubber quality. Even a chemically sound formulation can fail if the accelerator is unevenly distributed.

MTT-80 is engineered to disperse efficiently during standard mixing cycles. The accelerator particles are already finely distributed within the carrier, allowing them to integrate smoothly into rubber matrices such as NR, SBR, and other general-purpose elastomers.

The result is more homogeneous compounds, reduced risk of localized over-curing, and improved repeatability from batch to batch. For customers producing technical rubber goods, this level of consistency is a major advantage.

Reliable Choice for High-Volume Rubber Manufacturing

In high-volume production, reliability matters more than theory. MTT-80 has proven itself as a stable, production-friendly accelerator suited for large-scale rubber manufacturing.

Its predictable curing behavior, clean handling, and consistent dispersion make it particularly attractive for applications such as industrial rubber parts, molded components, and general rubber goods produced in large quantities. By reducing variability and simplifying handling, MTT-80 helps manufacturers maintain output while controlling long-term processing costs.

From a practical standpoint, it is not just an accelerator—it is a tool for process control and production stability.

vaskokudrickrk136@gmail.com

vaskokudrickrk136@gmail.com 嘉興北華高分子助剤有限公司 / 上海クリスタルウェルズ化学新材料有限公司 / 上海クリスタルウェルズ化学新材料有限公司

嘉興北華高分子助剤有限公司 / 上海クリスタルウェルズ化学新材料有限公司 / 上海クリスタルウェルズ化学新材料有限公司